Category: Lean Manufacturing

5S Factory Makeover Preview. 5S is a methodology for organizing and maintaining a clean and efficient work environment in manufacturing. The 5S stands for: Sort, Set in Order, Shine, Standardize, Sustain. The importance of...

This is a great video about the history of the Toyota Production System. The Toyota Production System (TPS) is a method of manufacturing developed by the Toyota Motor Corporation in the mid-20th century. It...

Process Improvement: Six Sigma & Kaizen Methodologies Process improvement is a method of identifying and eliminating inefficiencies and defects in a business process in order to increase efficiency, reduce costs, and improve overall performance....

Evolution of Continuous Improvement and Lean Manufacturing: How It Has Changed Over Time. Continuous improvement and lean manufacturing have been integral components of the manufacturing industry for decades. Over the years, these concepts have...

3D Printing: The Future of Supply Chain Solutions. 3D printing has revolutionized the way businesses operate, allowing them to create products quickly and cost-effectively. This technology has also had a major impact on the...

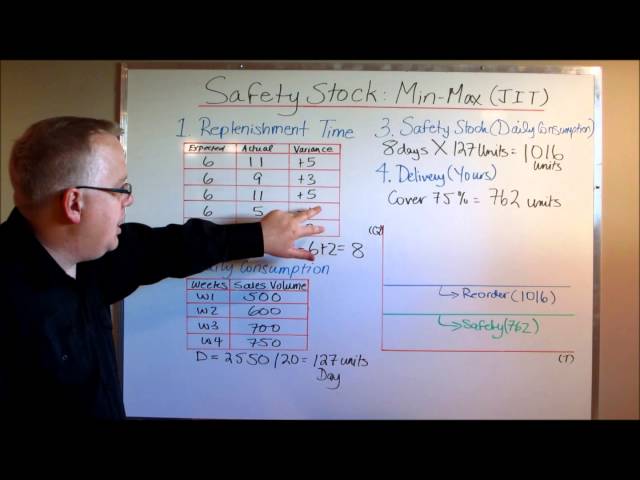

Kanban just in time (JIT) From youtube: Kanban Just in Time (JIT) is a scheduling system meant to achieve just-in-time production. The focus here is that you could apply just in time (JIT) in a regular...

7 Wastes of Lean Learn about some of the major tools used to combat the 7 Wastes of lean, and ways you can overhaul your processes to become more efficient. Delve into Value-Added and...

Calculating Safety Stock Safety stock is a buffer of inventory that a company keeps on hand to ensure that it can meet customer demand even if there are unexpected disruptions or fluctuations in demand....

Toyota Production Documentary – Toyota Manufacturing Production and Assembly at Toyota Factory Toyota follows a lean manufacturing process, known as the Toyota Production System (TPS). TPS focuses on reducing waste and maximizing efficiency in...

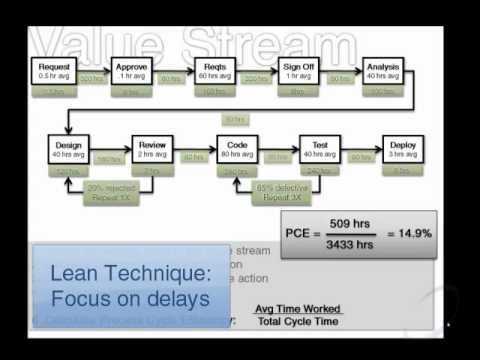

Mapping a Value Stream to a Kanban Board. Mapping a value stream to a Kanban board is a way to visualize and manage the flow of work through a process using the Kanban method....