History of the Toyota Production System (TPS). Lean manufacturing.

This is a great video about the history of the Toyota Production System.

The Toyota Production System (TPS) is a method of manufacturing developed by the Toyota Motor Corporation in the mid-20th century. It is also known as lean manufacturing or the Toyota Way, and it is characterized by a focus on continuous improvement, efficiency, and waste reduction.

The TPS was developed by Taiichi Ohno, who was a manager at Toyota in the 1950s. Ohno was inspired by the principles of the American engineer Henry Ford, who had developed the first moving assembly line for the mass production of automobiles. However, Ohno felt that Ford’s system was inefficient and wasted resources, and he set out to develop a more efficient method of manufacturing.

Ohno’s system focused on eliminating waste and increasing efficiency by standardizing work processes and using small batch production techniques. He also implemented a system of continuous improvement, known as kaizen, which encouraged workers to identify and eliminate waste in their work processes.

The TPS became widely adopted in Japan and around the world, and it has had a significant impact on the manufacturing industry. Today, the principles of the Toyota Production System continue to be used by companies in a variety of industries as a way to improve efficiency, reduce waste, and increase productivity.

Lean and Toyota Production System Blogs

- Continuous Improvement Tools: Lean and Six Sigma.

- How Toyota Changed Manufacturing – Lean Thinking

- Introduction to Lean Manufacturing.

- JIT Toyota: The Smartest Production System in The World.

- Lean Kaizen DMAIC Six Sigma.

- Lean Manufacturing | A pursuit of perfection.

- Lean Manufacturing – Lean Factory Tour.

- Rooting Out Waste in Health Care by Taking Cue From Toyota.

- SCM Top Companies.

- Supply Chain Resources by Topic & Supplier.

- The Toyota Way To Lean Leadership – Keynote talk by Jeffrey Liker. 60 min video.

- Toyota Production Documentary – Toyota Manufacturing Production.

- Toyota Kaizen

- What is Lean Manufacturing?

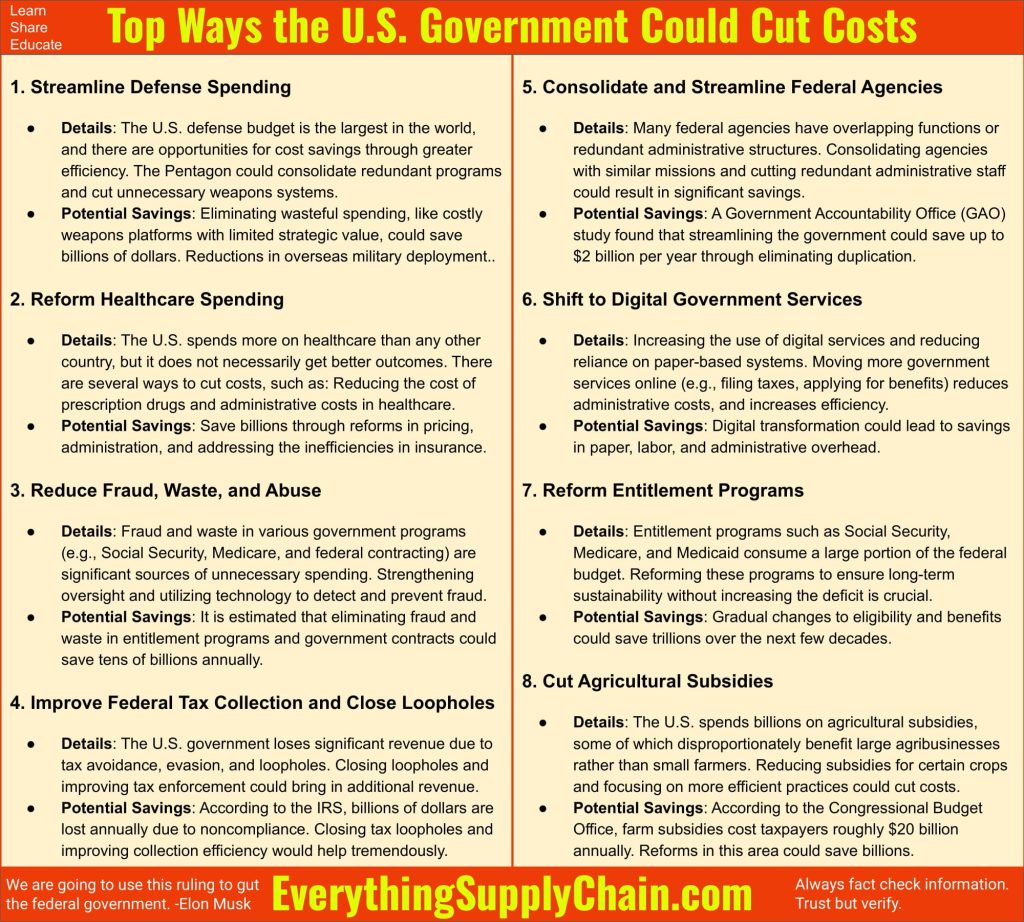

Ways Elon Musk Might Gut the Federal Government.

Department of Government Efficiency (DOGE): Elon Musk. Good or bad?

Guide to Lean Manufacturing

Introduction to Lean Manufacturing.

“Costs do not exist to be calculated. Costs exist to be reduced.” ~Taiichi Ohno, Father of the Toyota Production System

“A bad system will beat a good person every time.” ~W. Edwards Deming

“For much of Toyota’s history, we have ensured the quality and reliability of our vehicles by placing a device called an andon cord on every production line – and empowering any team members to halt production if there’s an assembly problem. Only when the problem is resolved does the line begin to move again.” ~Akio Toyoda

“Standards should not be forced down from above but rather set by the production workers themselves.” ~Taiichi Ohno