Introduction to Lean Manufacturing.

Lean Manufacturing

What is lean manufacturing? This is all about continuous improvement. Get plenty of more details here: What is Lean Manufacturing?

Lean manufacturing is a management philosophy and set of principles aimed at maximizing customer value while minimizing waste. In other words, lean focuses on creating more value for customers with fewer resources by optimizing processes, reducing inefficiencies, and eliminating activities that do not add value. The goal is to improve productivity, reduce costs, and increase quality.

Key Principles of Lean Manufacturing

Lean manufacturing is rooted in the Toyota Production System (TPS), developed by Toyota in the mid-20th century, which emphasizes continuous improvement and respect for people. The core principles of lean manufacturing include:

- Value: Value is defined from the perspective of the customer. Anything that does not directly contribute to the value of the product or service from the customer’s viewpoint is considered waste and should be eliminated.

- Value Stream Mapping: This involves identifying all the actions (value-creating and non-value-creating) in the production process. By mapping out the entire value stream, companies can see where waste occurs and where improvements can be made.

- Flow: Lean manufacturing aims to improve the flow of materials, information, and work through the system. This means reducing delays, bottlenecks, and unnecessary steps in the process. By optimizing flow, a company can produce products faster and with fewer interruptions.

- Pull: A pull system is one where production is driven by actual customer demand, not forecasts. In a pull system, products are only made when there is a demand for them, which helps reduce overproduction and excess inventory. This is often implemented with techniques like Just-in-Time (JIT) production.

- Perfection: Lean manufacturing emphasizes the idea of continuous improvement, or kaizen. The pursuit of perfection involves constantly looking for ways to eliminate waste, improve processes, and increase value. Teams are encouraged to regularly review workflows, make adjustments, and innovate to enhance efficiency.

Types of Waste in Lean Manufacturing (The “Seven Wastes”)

One of the main goals of lean is to eliminate waste in all its forms. In lean manufacturing, there are seven primary types of waste, often referred to by the acronym TIMWOOD:

- Transport: Unnecessary movement of materials, products, or information. This can lead to delays and inefficiencies in the process.

- Inventory: Excess inventory that is not immediately needed for production ties up capital and takes up space, leading to additional handling costs and risks of obsolescence.

- Motion: Excessive movement by workers or equipment, such as walking, reaching, bending, or searching for tools, that does not add value to the product.

- Waiting: Time when workers, machines, or materials are idle because of delays, lack of resources, or process inefficiencies.

- Overproduction: Producing more than is needed or producing before it is needed. This leads to waste in terms of excess inventory, handling, and storage costs.

- Overprocessing: Doing more work or adding more features to a product than what is necessary to meet customer requirements, often resulting in higher costs and longer lead times.

- Defects: Producing defective products that need to be reworked or scrapped, leading to wasted materials, time, and labor.

Lean Manufacturing Tools and Techniques

Several tools and methodologies are used to implement lean manufacturing principles effectively:

- 5S: A system for organizing the workplace to promote efficiency and reduce waste. It includes:

- Sort (Seiri): Remove unnecessary items.

- Set in order (Seiton): Arrange tools and materials for easy access.

- Shine (Seiso): Keep the workplace clean and organized.

- Standardize (Seiketsu): Establish standards for processes and procedures.

- Sustain (Shitsuke): Maintain the system and continuously improve.

- Kaizen (Continuous Improvement): A culture of small, incremental improvements that engage all employees in identifying and solving problems. Kaizen events are often used to improve a specific process or work area.

- Kanban: A visual scheduling system used to control inventory and production. It signals when materials or components are needed to keep the production line running smoothly, based on actual demand (pull system).

- Just-in-Time (JIT): A production strategy aimed at reducing inventory and producing goods only as they are needed, in the right quantity, and at the right time.

- Total Productive Maintenance (TPM): A system for maintaining equipment to minimize downtime and maximize productivity by involving all employees in maintaining and improving equipment performance.

- Root Cause Analysis (5 Whys): A problem-solving technique that involves asking “why” five times to uncover the root cause of a problem and prevent recurrence.

- Value Stream Mapping: A visual tool used to analyze and design the flow of materials and information through a production system. It helps identify areas of waste and opportunities for improvement.

Benefits of Lean Manufacturing

- Cost Reduction: By eliminating waste and inefficiencies, lean manufacturing can reduce costs related to inventory, labor, and production.

- Improved Quality: Lean practices like continuous improvement and defect reduction lead to higher-quality products.

- Faster Lead Times: Streamlining processes and reducing waiting times leads to faster production cycles.

- Greater Flexibility: Lean systems are designed to respond quickly to changes in customer demand, making the business more agile.

- Employee Engagement: Lean encourages worker involvement and problem-solving, leading to higher job satisfaction and empowerment.

Challenges of Lean Manufacturing

- Initial Investment: Implementing lean manufacturing can require significant upfront investments in training, systems, and tools.

- Cultural Change: Lean requires a shift in company culture, which can be difficult if employees or management are resistant to change.

- Sustaining Improvements: Maintaining lean practices over time requires ongoing commitment and continuous effort to identify new areas of improvement.

Conclusion

Lean manufacturing is not just a set of tools or a methodology—it’s a mindset that focuses on creating value by eliminating waste and improving processes. When implemented effectively, it can lead to significant improvements in efficiency, cost reduction, and product quality, while fostering a culture of continuous improvement. Many companies across industries—from automotive to electronics, consumer goods, and healthcare—have successfully adopted lean principles to stay competitive and deliver higher value to their customers.

Quotes about Lean Manufacturing

- “If you are going to do kaizen continuously you’ve got to assume that things are a mess. Too many people just assume that things are all right the way they are. Aren’t you guys convinced that the way you’re doing things is the right way? That’s no way to get anything done. Kaizen is about changing the way things are. If you assume that things are all right the way they are, you can’t do kaizen. So change something!” ~Taiichi Ohno, father of Toyota Production System (TPS)

- “A relentless barrage of “why’s” is the best way to prepare your mind to pierce the clouded veil of thinking caused by the status quo. Use it often.” ~Shigeo Shingo

- “It’s pretty simple. If you have an environment where people aren’t afraid to speak up, and you listen to them things will get better.” ~Dave Waters

- “Continuous improvement is better than delayed perfection.” ~Mark Twain

- “Why not make the work easier and more interesting so that people do not have to sweat? The Toyota style is not to create results by working hard. It is a system that says there is no limit to people’s creativity. People don’t go to Toyota to ‘work’ they go there to ‘think’” ~Taiichi Ohno

- “Good is the enemy of great. That’s why so few things become great.” ~James C. Collins

- “All we are doing is looking at the time line, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing the time line by reducing the non-value adding wastes.” ~Taiichi Ohno, father of Toyota Production System (TPS)

Lean and Continuous Improvement Blogs

- Collection of Quotes about the Toyota Production System.

- Gemba Walk: the Path to Continuous Improvement.

- History of Continuous Improvement & Quality Gurus.

- Intro to Lean: What are the 7 Wastes of Lean?

- Kaizen (Continuous Improvement): Secret behind Japanese Productivity

- Kanban explained in 60 seconds.

- Lean Manufacturing – Lean Factory Tour.

- Lean Manufacturing Quotes.

- Mapping a Value Stream to a Kanban Board.

- Rooting Out Waste in Health Care by Taking Cue From Toyota.

- SCM Top Companies.

- Supply Chain Quotes: Take it to the next level.

- Supply Chain Resources by Topic & Supplier.

- Toyota Way–‘The 14 Principles of the Toyota Way’

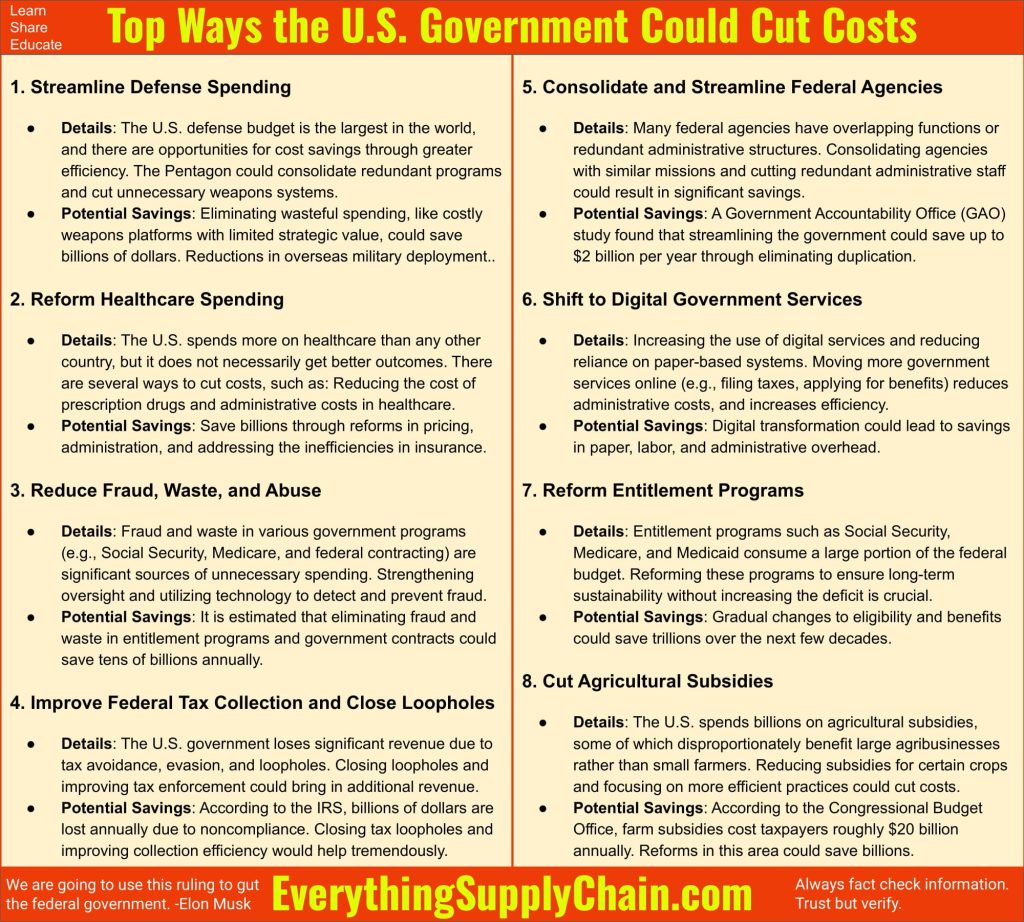

Ways Elon Musk Might Gut the Federal Government.

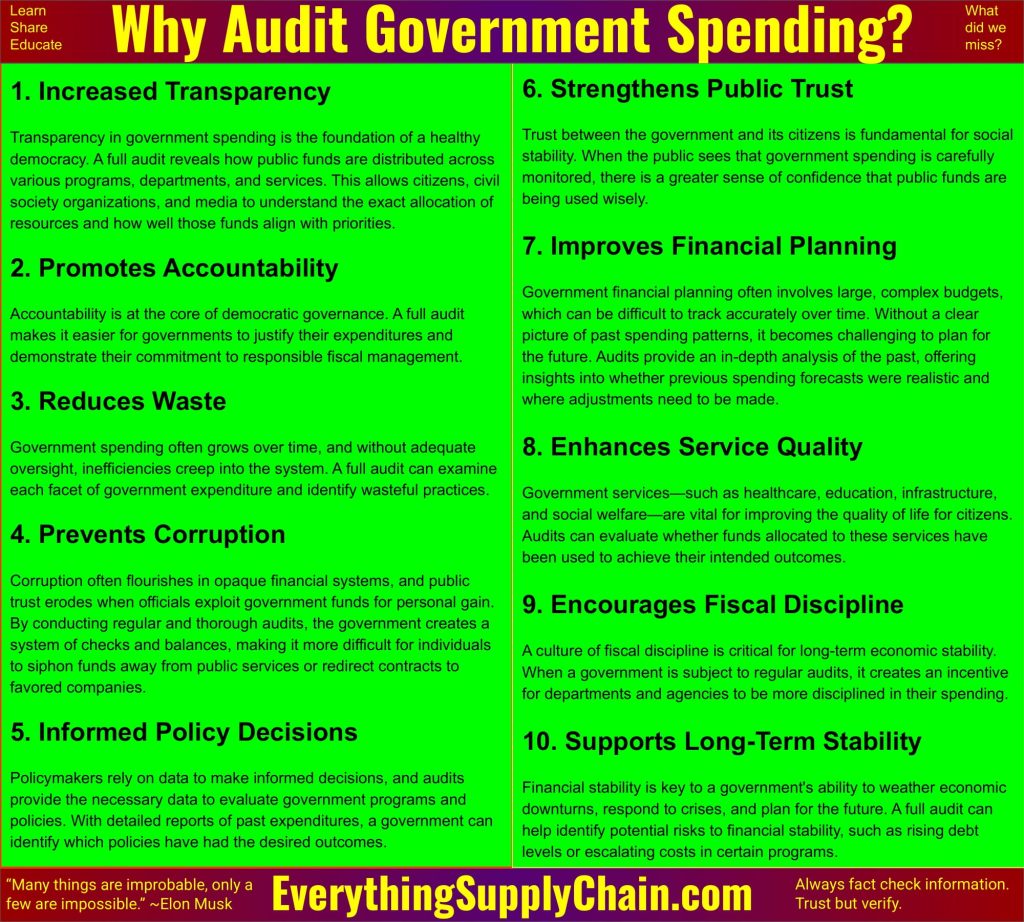

Why Audit Government Spending?

How Do They Do It? – Airplane Recycling.

Department of Government Efficiency (DOGE): Elon Musk. Good or bad?

“What gets measured gets improved.” ~Peter Drucker

“If you have always done it that way, it is probably wrong.” ~Charles Kettering

“Standards should not be forced down from above but rather set by the production workers themselves.” ~Taiichi Ohno

“Data is of course important in manufacturing, but I place the greatest emphasis on facts.” ~Taiichi Ohno

“The value of an idea lies in the using of it.” ~Thomas Edison