Kanban explained in 60 seconds. 11k views

Kanban just in time (JIT)

From youtube: Kanban Just in Time (JIT) is a scheduling system meant to achieve just-in-time production. The focus here is that you could apply just in time (JIT) in a regular project management, organizing the workflow in a most efficient and natural way.

Kanban is a lean manufacturing method that uses visual cues to signal when work should be started or stopped. Kanban cards are used to represent work items, and they are moved through a series of stages, such as “to do,” “in progress,” and “done.”

Kanban can be used in any process where work is done, but it is particularly well-suited for supply chain management. In a supply chain, Kanban can be used to manage the flow of materials, products, and information between different stages of the process.

Here are some of the benefits of using Kanban in supply chain management:

- Reduced inventory: Kanban helps to ensure that there is only the right amount of inventory at each stage of the supply chain. This can lead to significant savings in inventory costs.

- Improved visibility: Kanban provides visibility into the flow of materials and products through the supply chain. This can help to identify and address bottlenecks and inefficiencies.

- Increased flexibility: Kanban can help to make the supply chain more flexible, so that it can adapt to changes in demand.

- Improved customer service: Kanban can help to improve customer service by ensuring that products are delivered on time and in the right quantity.

Here are some of the ways Kanban can be used in supply chain management:

- Managing inventory: Kanban can be used to manage the flow of materials and products through the supply chain. This can be done by using Kanban cards to track the movement of goods.

- Managing production: Kanban can be used to manage the production process. This can be done by using Kanban cards to signal when work should be started or stopped.

- Managing deliveries: Kanban can be used to manage the delivery of goods to customers. This can be done by using Kanban cards to track the movement of goods from the supplier to the customer.

- Managing information: Kanban can be used to manage the flow of information through the supply chain. This can be done by using Kanban cards to track the movement of information, such as purchase orders, shipping notices, and invoices.

Kanban is a powerful tool that can be used to improve the efficiency and effectiveness of a supply chain. If you are looking to reduce costs, improve customer service, and increase flexibility, then Kanban is a good option to consider.

Here are some examples of companies that use Kanban in supply chain management:

- Toyota: Toyota is the company that developed Kanban, and it continues to use it today.

- Amazon: Amazon uses Kanban to manage its inventory and distribution system.

- Apple: Apple uses Kanban to manage its production of iPhones and other products.

- Dell: Dell uses Kanban to manage its production of computers and other products.

- Starbucks: Starbucks uses Kanban to manage its supply of coffee and other products.

These are just a few examples of companies that use Kanban in supply chain management. There are many other companies that use this method, and it is becoming increasingly popular as businesses look for ways to improve their supply chains.

Lean Quotes

- “If you are going to do kaizen continuously you’ve got to assume that things are a mess. Too many people just assume that things are all right the way they are. Aren’t you guys convinced that the way you’re doing things is the right way? That’s no way to get anything done. Kaizen is about changing the way things are. If you assume that things are all right the way they are, you can’t do kaizen. So change something!” ~ Taiichi Ohno, father of Toyota Production System (TPS)

- “Those who cannot change their minds cannot change anything.” ~ George Bernard Shaw

- “The measure of intelligence is the ability to change.” ~ Albert Einstein

- “Agile values ask us to make progress with imperfect information and to rework later as we learn more. Lean Product Development teaches us to understand the cost of delay and to recognize that earlier, faster progress to a partial solution is often better than delaying to acquire better information leading to a more complete solution.” ~ David J. Anderson

- “Make your workplace into showcase that can be understood by everyone at a glance. In terms of quality, it means to make the defects immediately apparent. In terms of quantity, it means that progress or delay, measured against the plan, and is made immediately apparent. When this is done, problems can be discovered immediately, and everyone can initiate improvement plans.” ~ Taiichi Ohno, father of Toyota Production System (TPS)

- “Decide the outer boundaries of the kanban system. It is often best to limit this to the immediate span of political control. Do not force visualization, transparency, and WIP limits on any department that does not volunteer to collaborate.” ~ David J. Anderson

Lean and Supply Chain Education and Learning.

- 5s Office to 5s Manufacturing. Lean Production System.

- Becoming a Lean Supply Chain Professional.

- Become a Supply Chain Rockstar and rock your career.

- Free Supply Chain Training.

- Introduction to Lean Manufacturing.

- Lean Kaizen DMAIC Six Sigma.

- Process Improvement: Six Sigma & Kaizen Methodologies,

- Toyota Production Documentary – Toyota Manufacturing Production and Assembly at Toyota Factory.

- Toyota Production System.

- What is Supply Chain Management?

- Why Lean Fails.

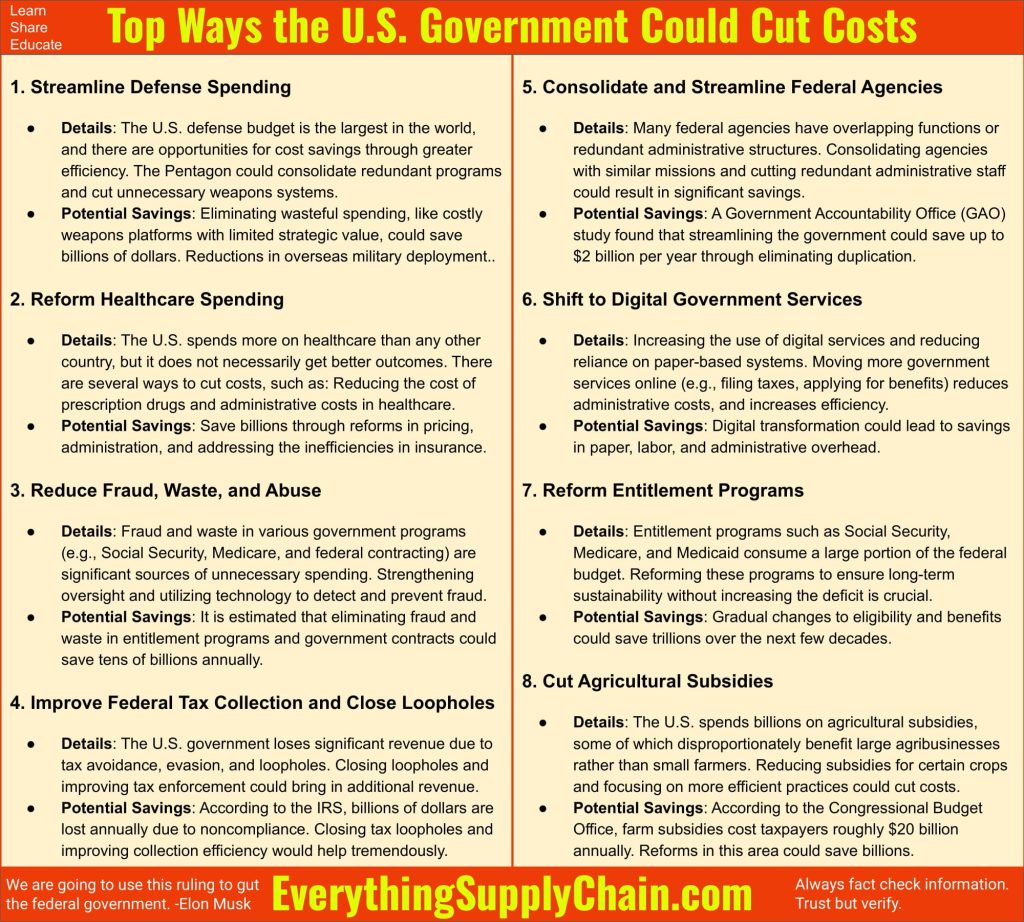

Ways Elon Musk Might Gut the Federal Government.

Department of Government Efficiency (DOGE): Elon Musk. Good or bad?

What to expect from Elon Musk’s Department of Government Efficiency.

Introduction to Lean Manufacturing.