Minimize Supply chain Disruptions and the Bullwhip Effect.

Minimize Supply chain Disruptions and the Bullwhip Effect.

Supply chain disruptions can have a significant impact on businesses, leading to increased costs, decreased customer satisfaction, and decreased profits. The bullwhip effect is a phenomenon that occurs when small changes in demand at the retail level cause larger changes in demand at the wholesale and manufacturing levels. Minimizing supply chain disruptions and the bullwhip effect is essential for businesses to remain competitive and profitable. This article will discuss strategies for minimizing supply chain disruptions and the bullwhip effect, including improved communication, better forecasting, and increased collaboration.

How to Minimize Supply Chain Disruptions and the Bullwhip Effect

Supply chain disruptions can have a significant impact on businesses, leading to increased costs, decreased customer satisfaction, and decreased profits. The bullwhip effect is a phenomenon in which small changes in demand at the retail level can lead to large fluctuations in demand at the supplier level. To minimize supply chain disruptions and the bullwhip effect, businesses should take the following steps:

1. Improve visibility: Businesses should strive to improve visibility throughout the supply chain. This can be done by implementing a supply chain management system that provides real-time data on inventory levels, order status, and other key metrics. This will help businesses identify potential disruptions before they occur and take corrective action.

2. Improve forecasting: Accurate forecasting is essential for minimizing supply chain disruptions. Businesses should use predictive analytics to identify trends and anticipate customer demand. This will help businesses plan for potential disruptions and ensure that they have the necessary resources to meet customer demand.

3. Improve communication: Communication is key to minimizing supply chain disruptions. Businesses should ensure that all stakeholders in the supply chain are kept informed of any changes in demand or supply. This will help businesses respond quickly to any disruptions and minimize their impact.

4. Implement safety stock: Safety stock is a buffer of inventory that is kept on hand to ensure that customer demand can be met in the event of a disruption. Businesses should maintain an appropriate level of safety stock to minimize the impact of supply chain disruptions.

By taking these steps, businesses can minimize supply chain disruptions and the bullwhip effect. This will help businesses maintain customer satisfaction, reduce costs, and increase profits.

The Impact of the Bullwhip Effect on Supply Chain Disruptions

The bullwhip effect is a phenomenon that occurs in supply chains when small changes in demand at the retail level cause larger fluctuations in demand at the wholesale and manufacturing levels. This effect can have a significant impact on supply chain disruptions, as it can lead to an increase in inventory costs, delays in delivery, and a decrease in customer satisfaction.

The bullwhip effect is caused by a number of factors, including order batching, demand forecasting errors, price fluctuations, and rationing. Order batching occurs when orders are placed in large batches instead of smaller, more frequent orders. This can lead to an increase in inventory costs, as the larger orders require more inventory to be held in stock. Demand forecasting errors can also lead to the bullwhip effect, as inaccurate forecasts can lead to overstocking or understocking of inventory. Price fluctuations can also cause the bullwhip effect, as changes in prices can lead to changes in demand. Finally, rationing can lead to the bullwhip effect, as customers may purchase more than they need in order to ensure they have enough of a product.

The impact of the bullwhip effect on supply chain disruptions can be significant. It can lead to an increase in inventory costs, as larger orders require more inventory to be held in stock. It can also lead to delays in delivery, as the larger orders require more time to process and fulfill. Finally, it can lead to a decrease in customer satisfaction, as customers may experience delays in receiving their orders or may not be able to purchase the products they need.

In order to mitigate the impact of the bullwhip effect on supply chain disruptions, it is important for companies to implement strategies that reduce the factors that cause the bullwhip effect. This includes implementing more frequent ordering, improving demand forecasting accuracy, and using pricing strategies that are more stable. Additionally, companies should strive to improve communication between all levels of the supply chain in order to ensure that orders are placed in a timely manner and that inventory levels are accurate.

By implementing strategies to reduce the bullwhip effect, companies can reduce the impact of supply chain disruptions and ensure that customers receive their orders in a timely manner. This can lead to increased customer satisfaction and improved profitability for the company.

Strategies to Reduce Supply Chain Disruptions and the Bullwhip Effect

Supply chain disruptions and the bullwhip effect can have a significant impact on businesses, leading to increased costs, decreased customer satisfaction, and decreased profits. Fortunately, there are strategies that businesses can use to reduce the impact of these issues.

1. Improve Visibility: One of the most effective strategies for reducing supply chain disruptions and the bullwhip effect is to improve visibility throughout the supply chain. This can be done by implementing a supply chain management system that provides real-time data on inventory levels, order status, and other key metrics. This will allow businesses to quickly identify potential issues and take corrective action before they become major problems.

2. Improve Forecasting: Accurate forecasting is essential for reducing supply chain disruptions and the bullwhip effect. Businesses should use historical data and predictive analytics to create accurate forecasts of customer demand. This will help ensure that the right amount of inventory is available at the right time.

3. Improve Collaboration: Collaboration between suppliers, manufacturers, and retailers is essential for reducing supply chain disruptions and the bullwhip effect. Businesses should work together to share information, coordinate activities, and develop strategies for managing demand. This will help ensure that everyone is on the same page and working towards the same goals.

4. Reduce Lead Times: Reducing lead times is another effective strategy for reducing supply chain disruptions and the bullwhip effect. Businesses should strive to reduce the time it takes to get products from suppliers to customers. This can be done by streamlining processes, improving communication, and investing in technology.

By implementing these strategies, businesses can reduce the impact of supply chain disruptions and the bullwhip effect. This will help ensure that customers receive the products they need in a timely manner, while also helping businesses reduce costs and increase profits.

The Role of Technology in Minimizing Supply Chain Disruptions and the Bullwhip Effect

In today’s global economy, supply chain disruptions can have a significant impact on businesses. These disruptions can be caused by a variety of factors, including natural disasters, political unrest, and economic downturns. As a result, it is essential for businesses to have strategies in place to minimize the impact of supply chain disruptions. One of the most effective strategies is the use of technology to reduce the bullwhip effect.

The bullwhip effect is a phenomenon in which small changes in demand at the retail level can lead to large fluctuations in demand at the wholesale and manufacturing levels. This can lead to supply chain disruptions, as manufacturers may not be able to keep up with the changing demand. Technology can be used to reduce the bullwhip effect by providing better visibility into the supply chain. This can be done through the use of real-time data, predictive analytics, and automated processes.

Real-time data can be used to provide an accurate picture of demand at all levels of the supply chain. This can help manufacturers anticipate changes in demand and adjust their production accordingly. Predictive analytics can be used to identify patterns in demand and anticipate future changes. This can help manufacturers plan ahead and reduce the risk of supply chain disruptions. Automated processes can also be used to streamline the supply chain and reduce the risk of disruptions. Automation can help reduce the time it takes to process orders, which can help reduce the bullwhip effect.

In addition to reducing the bullwhip effect, technology can also be used to improve communication between different parts of the supply chain. This can help ensure that everyone is on the same page and that any changes in demand are communicated quickly. This can help reduce the risk of supply chain disruptions and ensure that orders are fulfilled in a timely manner.

Overall, technology can be a powerful tool for minimizing supply chain disruptions and the bullwhip effect. By providing better visibility into the supply chain, improving communication, and automating processes, businesses can reduce the risk of supply chain disruptions and ensure that orders are fulfilled in a timely manner.

The Benefits of Minimizing Supply Chain Disruptions and the Bullwhip Effect

Supply chain disruptions can have a significant impact on businesses, leading to increased costs, decreased customer satisfaction, and decreased profits. Minimizing supply chain disruptions is essential for businesses to remain competitive and profitable. There are several benefits to minimizing supply chain disruptions, including reducing the bullwhip effect, improving customer satisfaction, and increasing profits.

The bullwhip effect is a phenomenon in which small changes in demand at the retail level can lead to large fluctuations in demand at the supplier level. This can lead to supply chain disruptions, as suppliers may not be able to meet the sudden increase in demand. By minimizing supply chain disruptions, businesses can reduce the bullwhip effect and ensure that their suppliers are able to meet their demand.

Minimizing supply chain disruptions also helps to improve customer satisfaction. When customers experience delays in receiving their orders, they may become frustrated and dissatisfied with the business. By minimizing supply chain disruptions, businesses can ensure that their customers receive their orders on time and in full, leading to increased customer satisfaction.

Finally, minimizing supply chain disruptions can help to increase profits. When supply chain disruptions occur, businesses may incur additional costs, such as expedited shipping fees or lost sales due to out-of-stock items. By minimizing supply chain disruptions, businesses can reduce these costs and increase their profits.

In conclusion, minimizing supply chain disruptions is essential for businesses to remain competitive and profitable. By minimizing supply chain disruptions, businesses can reduce the bullwhip effect, improve customer satisfaction, and increase profits.

The Challenges of Minimizing Supply Chain Disruptions and the Bullwhip Effect

Supply chain disruptions can have a significant impact on businesses, leading to increased costs, decreased customer satisfaction, and decreased profits. The bullwhip effect is a phenomenon that occurs when demand fluctuations are amplified as they move up the supply chain. This can lead to further supply chain disruptions, making it difficult for businesses to manage their supply chains effectively. In order to minimize supply chain disruptions and the bullwhip effect, businesses must take a proactive approach to managing their supply chains.

One way to minimize supply chain disruptions is to ensure that all stakeholders in the supply chain are aware of the potential risks and are prepared to respond quickly and effectively. This includes having a clear understanding of the supply chain, including the suppliers, customers, and other stakeholders. It also involves having a plan in place to respond to disruptions, such as having alternative suppliers or alternative transportation methods. Additionally, businesses should have a system in place to monitor the supply chain and identify potential risks before they become disruptions.

Another way to minimize supply chain disruptions is to reduce the variability of demand. This can be done by using forecasting techniques to better predict customer demand and by using inventory management techniques to reduce the amount of inventory held in the supply chain. Additionally, businesses should strive to create a more collaborative relationship with their suppliers, which can help to reduce the variability of demand.

Finally, businesses should strive to reduce the bullwhip effect by improving communication and collaboration between stakeholders in the supply chain. This can be done by implementing systems that allow for real-time communication and collaboration between stakeholders. Additionally, businesses should strive to create a culture of trust and transparency between stakeholders, which can help to reduce the bullwhip effect.

By taking a proactive approach to managing their supply chains, businesses can minimize supply chain disruptions and the bullwhip effect. This can help to reduce costs, improve customer satisfaction, and increase profits.

Best Practices for Minimizing Supply Chain Disruptions and the Bullwhip Effect

1. Establish a Clear Chain of Command: Establishing a clear chain of command within the supply chain is essential for minimizing disruptions and the bullwhip effect. This means that each link in the chain should have a designated leader who is responsible for overseeing the operations of that link. This leader should be able to communicate effectively with the other links in the chain and should be able to quickly identify and address any issues that arise.

2. Utilize Automation: Automation can be a powerful tool for minimizing supply chain disruptions and the bullwhip effect. Automation can help to streamline processes, reduce errors, and ensure that orders are fulfilled quickly and accurately. Automation can also help to reduce the need for manual intervention, which can help to reduce the risk of human error.

3. Monitor Demand: Monitoring demand is essential for minimizing supply chain disruptions and the bullwhip effect. By monitoring demand, companies can better anticipate customer needs and adjust their supply chain accordingly. This can help to ensure that the right amount of inventory is available at the right time, which can help to reduce the risk of supply chain disruptions.

4. Utilize Data Analytics: Data analytics can be a powerful tool for minimizing supply chain disruptions and the bullwhip effect. By utilizing data analytics, companies can gain insights into customer behavior, market trends, and other factors that can help to inform their supply chain decisions. This can help to ensure that the right amount of inventory is available at the right time, which can help to reduce the risk of supply chain disruptions.

5. Establish Clear Communication: Establishing clear communication between all links in the supply chain is essential for minimizing supply chain disruptions and the bullwhip effect. This means that each link should have a designated point of contact who is responsible for communicating with the other links in the chain. This can help to ensure that any issues that arise are quickly identified and addressed.

By following these best practices, companies can minimize supply chain disruptions and the bullwhip effect. This can help to ensure that orders are fulfilled quickly and accurately, which can help to improve customer satisfaction and increase profits.

The Future of Minimizing Supply Chain Disruptions and the Bullwhip Effect

The bullwhip effect is a phenomenon in supply chain management that occurs when small changes in demand at the retail level cause larger fluctuations in demand at the wholesale, distributor, and manufacturer levels. This effect can lead to supply chain disruptions, which can have a significant impact on a company’s bottom line. As such, it is important for companies to understand the causes of the bullwhip effect and to develop strategies to minimize its impact.

One of the primary causes of the bullwhip effect is the lack of communication between different levels of the supply chain. When information is not shared between the different levels, it can lead to inaccurate forecasting and ordering, which can cause large fluctuations in demand. To minimize the bullwhip effect, companies should strive to improve communication between different levels of the supply chain. This can be done through the use of technology, such as cloud-based systems that allow for real-time data sharing.

Another cause of the bullwhip effect is the lack of visibility into the supply chain. When companies do not have visibility into the supply chain, they cannot accurately forecast demand or plan for potential disruptions. To minimize the bullwhip effect, companies should strive to increase visibility into the supply chain. This can be done through the use of technology, such as RFID tags and sensors that allow for real-time tracking of inventory.

Finally, the bullwhip effect can be minimized by improving the accuracy of demand forecasting. Companies should strive to use predictive analytics to better understand customer demand and to anticipate potential disruptions. This can be done through the use of machine learning algorithms that can analyze customer data and identify patterns in demand.

In conclusion, the bullwhip effect can have a significant impact on a company’s bottom line. To minimize the impact of the bullwhip effect, companies should strive to improve communication between different levels of the supply chain, increase visibility into the supply chain, and improve the accuracy of demand forecasting. By taking these steps, companies can minimize the impact of the bullwhip effect and ensure a more efficient and profitable supply chain.

Conclusion

Minimizing supply chain disruptions and the bullwhip effect is essential for businesses to remain competitive in today’s market. By implementing strategies such as demand forecasting, inventory management, and supplier collaboration, businesses can reduce the risk of supply chain disruptions and the bullwhip effect. Additionally, businesses should strive to create a culture of transparency and collaboration within their supply chain to ensure that all stakeholders are aware of the potential risks and are working together to mitigate them. By taking these steps, businesses can ensure that their supply chain remains efficient and effective, and that their customers receive the products they need in a timely manner.

Supply Chain Disruption

- Avoiding Disruptions in Your Supply Chain.

- Bullwhip Effect: How Sudden Demand Increases Affect Supply Chains.

- Coronavirus Accelerates Automation Across Industry.

- From Pandemic Disruption to Global Supply Chain Recovery.

- Implementation Guide to Develop a Resilient Supply Chain.

- Learn to Innovate Supply Chain in an Hour.

- SCM Risk Management Discussion.

- SCM Risk Management (SCRM) Videos and Training.

- Supply Chain Challenges: Ports Face Record Backlog.

- Supply chain experts see more disruptions.

- Supply Chain Master: Professor Hau Lee on the bullwhip effect.

- The Beer Game.

- Worst Supply Chain Disruptions in Modern USA History.

Introduction to Lean Manufacturing.

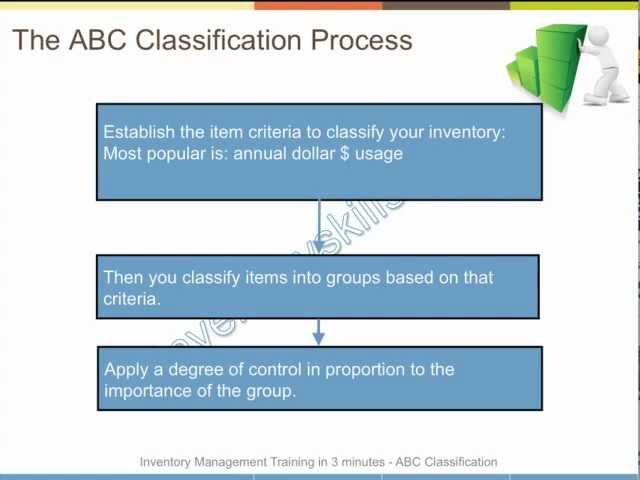

Inventory Management Training in 3 minutes – ABC Classification

Artificial Intelligence in Supply Chain Predictive Analytics.

Process Improvement Quotes and Blogs.