Supplier Management Strategies for the Lowest Total Cost of Ownership (TCO)

Maximizing Supplier Relationships for the Best TCO Outcome!

Supplier management strategies are essential for any business looking to reduce their total cost of ownership (TCO). By managing suppliers effectively, businesses can reduce their costs and increase their profits. This article will discuss the various strategies that can be used to achieve the lowest TCO. It will cover topics such as supplier selection, negotiation, and performance management. Additionally, it will provide tips on how to ensure that the strategies are implemented successfully. By following these strategies, businesses can ensure that they are getting the best value for their money and achieving the lowest TCO.

How to Leverage Supplier Relationships to Achieve the Lowest Total Cost of Ownership

Supplier relationships are an important part of achieving the lowest total cost of ownership (TCO). By leveraging these relationships, organizations can reduce costs, improve quality, and increase efficiency. This article will discuss how to leverage supplier relationships to achieve the lowest TCO.

First, it is important to establish a strong relationship with suppliers. This can be done by developing a clear understanding of the supplier’s capabilities and expectations. This includes understanding the supplier’s pricing structure, delivery times, and quality standards. Additionally, it is important to ensure that the supplier is reliable and trustworthy. This can be done by conducting background checks and verifying references.

Second, organizations should strive to develop long-term relationships with suppliers. This can be done by providing incentives for suppliers to remain loyal and by offering discounts for long-term contracts. Additionally, organizations should strive to develop a collaborative relationship with suppliers. This can be done by sharing information and working together to develop innovative solutions.

Third, organizations should strive to negotiate the best possible terms with suppliers. This includes negotiating prices, delivery times, and quality standards. Additionally, organizations should strive to negotiate payment terms that are favorable to both parties. This can be done by offering discounts for early payments or by offering payment plans.

Finally, organizations should strive to monitor supplier performance. This can be done by tracking supplier performance metrics such as on-time delivery, quality, and cost. Additionally, organizations should strive to provide feedback to suppliers on their performance. This can help to ensure that suppliers are meeting the organization’s expectations.

By leveraging supplier relationships, organizations can achieve the lowest TCO. This can be done by establishing strong relationships, developing long-term relationships, negotiating the best possible terms, and monitoring supplier performance. By doing so, organizations can reduce costs, improve quality, and increase efficiency.

The Benefits of Supplier Consolidation for Lowering Total Cost of Ownership

Supplier consolidation is a strategic approach to procurement that involves reducing the number of suppliers used by an organization. This approach can be beneficial for organizations looking to reduce their total cost of ownership (TCO). By consolidating suppliers, organizations can reduce costs associated with procurement, such as administrative costs, inventory costs, and transportation costs. Additionally, supplier consolidation can lead to improved supplier relationships, increased bargaining power, and improved quality of goods and services.

Administrative costs associated with procurement can be reduced through supplier consolidation. By reducing the number of suppliers, organizations can reduce the amount of time and resources spent on managing supplier relationships. This includes activities such as negotiating contracts, managing supplier performance, and resolving disputes. Additionally, organizations can reduce the amount of paperwork associated with managing multiple suppliers.

Inventory costs can also be reduced through supplier consolidation. By reducing the number of suppliers, organizations can reduce the amount of inventory they need to keep on hand. This can lead to lower storage costs and fewer inventory write-offs due to obsolescence. Additionally, organizations can reduce the amount of time and resources spent on managing inventory levels.

Transportation costs associated with procurement can also be reduced through supplier consolidation. By reducing the number of suppliers, organizations can reduce the amount of time and resources spent on managing transportation. This includes activities such as scheduling shipments, tracking shipments, and resolving delivery issues. Additionally, organizations can reduce the amount of time and resources spent on managing multiple carriers.

Supplier consolidation can also lead to improved supplier relationships. By reducing the number of suppliers, organizations can focus their efforts on developing strong relationships with fewer suppliers. This can lead to improved communication, increased trust, and better collaboration. Additionally, organizations can leverage their increased bargaining power to negotiate better terms and prices with suppliers.

Finally, supplier consolidation can lead to improved quality of goods and services. By reducing the number of suppliers, organizations can focus their efforts on developing relationships with fewer, higher-quality suppliers. This can lead to improved product quality, increased reliability, and better customer service. Additionally, organizations can leverage their increased bargaining power to negotiate better terms and prices with suppliers.

In conclusion, supplier consolidation can be beneficial for organizations looking to reduce their total cost of ownership. By reducing the number of suppliers, organizations can reduce costs associated with procurement, such as administrative costs, inventory costs, and transportation costs. Additionally, supplier consolidation can lead to improved supplier relationships, increased bargaining power, and improved quality of goods and services.

Strategies for Negotiating Lower Prices with Suppliers to Reduce Total Cost of Ownership

Negotiating lower prices with suppliers is an effective way to reduce the total cost of ownership. Here are some strategies to help you achieve this goal:

1. Research the Market: Before negotiating with suppliers, it is important to research the market to understand the current prices and trends. This will help you to identify potential areas for cost savings and to determine the best price for the goods or services you are looking for.

2. Leverage Your Volume: If you are a large customer, you may be able to leverage your volume to negotiate lower prices. Suppliers may be willing to offer discounts if you commit to buying a certain amount of goods or services.

3. Negotiate Payment Terms: Negotiating payment terms can also help to reduce the total cost of ownership. For example, you may be able to negotiate a longer payment period or a discount for early payment.

4. Consider Long-Term Contracts: Long-term contracts can help to reduce costs by providing stability and predictability. Suppliers may be willing to offer discounts in exchange for a long-term commitment.

5. Ask for Discounts: Don’t be afraid to ask for discounts. Suppliers may be willing to offer discounts if you are a loyal customer or if you are buying in bulk.

By following these strategies, you can negotiate lower prices with suppliers and reduce the total cost of ownership.

The Role of Automation in Streamlining Supplier Management for Lower Total Cost of Ownership

Automation has become an increasingly important tool for streamlining supplier management and reducing total cost of ownership (TCO). Automation can help organizations reduce costs associated with manual processes, such as manual data entry, manual document processing, and manual supplier onboarding. Automation can also help organizations reduce costs associated with supplier management, such as supplier performance monitoring, supplier risk management, and supplier relationship management.

Automation can help organizations reduce costs associated with manual processes by eliminating the need for manual data entry and document processing. Automation can also help organizations reduce costs associated with supplier management by automating supplier onboarding, supplier performance monitoring, supplier risk management, and supplier relationship management. Automation can also help organizations reduce costs associated with supplier management by providing real-time visibility into supplier performance and risk.

Automation can also help organizations reduce costs associated with supplier management by providing a centralized platform for managing supplier information. This centralized platform can help organizations reduce costs associated with supplier management by providing a single source of truth for supplier information. This centralized platform can also help organizations reduce costs associated with supplier management by providing a single point of contact for supplier management activities.

Automation can also help organizations reduce costs associated with supplier management by providing a streamlined process for managing supplier information. Automation can help organizations reduce costs associated with supplier management by providing a streamlined process for managing supplier information, such as supplier onboarding, supplier performance monitoring, supplier risk management, and supplier relationship management. Automation can also help organizations reduce costs associated with supplier management by providing a streamlined process for managing supplier information, such as supplier onboarding, supplier performance monitoring, supplier risk management, and supplier relationship management.

In conclusion, automation can help organizations reduce costs associated with supplier management and reduce total cost of ownership (TCO). Automation can help organizations reduce costs associated with manual processes, such as manual data entry, manual document processing, and manual supplier onboarding. Automation can also help organizations reduce costs associated with supplier management, such as supplier performance monitoring, supplier risk management, and supplier relationship management. Automation can also help organizations reduce costs associated with supplier management by providing a centralized platform for managing supplier information and a streamlined process for managing supplier information.

How to Use Supplier Performance Metrics to Achieve the Lowest Total Cost of Ownership

Supplier performance metrics are essential for achieving the lowest total cost of ownership (TCO). TCO is the total cost of acquiring, owning, and disposing of a product or service over its entire life cycle. It includes the cost of acquisition, maintenance, and disposal, as well as any associated costs such as taxes, insurance, and financing.

To achieve the lowest TCO, organizations must use supplier performance metrics to evaluate and monitor their suppliers. These metrics can include cost, quality, delivery, and service. By measuring and tracking these metrics, organizations can identify areas of improvement and ensure that their suppliers are meeting their expectations.

Organizations should also use supplier performance metrics to compare suppliers and select the most cost-effective option. This can be done by comparing the cost of acquisition, maintenance, and disposal for each supplier. Organizations should also consider the quality of the product or service, the delivery time, and the level of customer service provided.

Organizations should also use supplier performance metrics to monitor supplier performance over time. This can be done by tracking the cost of acquisition, maintenance, and disposal for each supplier. Organizations should also track the quality of the product or service, the delivery time, and the level of customer service provided. By tracking these metrics, organizations can identify areas of improvement and ensure that their suppliers are meeting their expectations.

Finally, organizations should use supplier performance metrics to negotiate better terms with their suppliers. This can be done by comparing the cost of acquisition, maintenance, and disposal for each supplier. Organizations should also consider the quality of the product or service, the delivery time, and the level of customer service provided. By negotiating better terms, organizations can reduce their TCO and achieve the lowest total cost of ownership.

In conclusion, supplier performance metrics are essential for achieving the lowest total cost of ownership. Organizations should use these metrics to evaluate and monitor their suppliers, compare suppliers and select the most cost-effective option, monitor supplier performance over time, and negotiate better terms with their suppliers. By doing so, organizations can reduce their TCO and achieve the lowest total cost of ownership.

The Benefits of Supplier Diversity for Lowering Total Cost of Ownership

Supplier diversity is an important factor in lowering total cost of ownership (TCO). By leveraging the benefits of supplier diversity, organizations can reduce costs, increase efficiency, and improve customer satisfaction.

The primary benefit of supplier diversity is cost savings. By diversifying the supplier base, organizations can access a wider range of products and services at competitive prices. This can lead to significant cost savings, as organizations can take advantage of economies of scale and access better deals from suppliers. Additionally, supplier diversity can help organizations reduce their reliance on a single supplier, which can help to reduce the risk of supply chain disruptions.

Supplier diversity can also lead to increased efficiency. By diversifying the supplier base, organizations can access a wider range of products and services, which can help to streamline operations and reduce the time and effort required to source and procure goods and services. Additionally, supplier diversity can help organizations to access specialized expertise and resources, which can help to improve the quality of products and services.

Finally, supplier diversity can help to improve customer satisfaction. By diversifying the supplier base, organizations can access a wider range of products and services, which can help to meet customer needs more effectively. Additionally, supplier diversity can help organizations to access specialized expertise and resources, which can help to improve the quality of products and services.

In conclusion, supplier diversity is an important factor in lowering total cost of ownership. By leveraging the benefits of supplier diversity, organizations can reduce costs, increase efficiency, and improve customer satisfaction.

Strategies for Managing Supplier Risk to Achieve the Lowest Total Cost of Ownership

Supplier risk management is an important part of achieving the lowest total cost of ownership (TCO). By managing supplier risk, organizations can reduce costs, improve quality, and ensure timely delivery of goods and services. This article outlines strategies for managing supplier risk to achieve the lowest TCO.

1. Establish a Supplier Risk Management Program: Organizations should establish a supplier risk management program to identify, assess, and mitigate supplier risks. This program should include a process for evaluating suppliers, assessing their performance, and monitoring their performance over time. The program should also include a process for responding to supplier issues and resolving them in a timely manner.

2. Develop a Supplier Risk Profile: Organizations should develop a supplier risk profile to identify potential risks associated with each supplier. This profile should include information such as the supplier’s financial stability, quality of products and services, delivery performance, and customer service. This information can be used to assess the supplier’s risk level and determine the appropriate risk mitigation strategies.

3. Negotiate Contracts: Organizations should negotiate contracts with suppliers to ensure that they are meeting the organization’s requirements. This includes negotiating terms such as pricing, delivery schedules, quality standards, and payment terms. Negotiating contracts can help organizations reduce costs and ensure that suppliers are meeting their obligations.

4. Monitor Supplier Performance: Organizations should monitor supplier performance to ensure that they are meeting the organization’s requirements. This includes tracking supplier performance metrics such as on-time delivery, quality, and customer service. Monitoring supplier performance can help organizations identify potential issues and take corrective action before they become major problems.

5. Establish Supplier Relationships: Organizations should establish relationships with suppliers to ensure that they are meeting the organization’s requirements. This includes developing trust and understanding between the organization and the supplier. Establishing relationships can help organizations identify potential issues and resolve them quickly.

By implementing these strategies, organizations can effectively manage supplier risk and achieve the lowest total cost of ownership. By managing supplier risk, organizations can reduce costs, improve quality, and ensure timely delivery of goods and services.

The Role of Technology in Optimizing Supplier Management for Lower Total Cost of Ownership

The use of technology in supplier management is becoming increasingly important in order to optimize total cost of ownership (TCO). Technology can be used to streamline processes, reduce costs, and improve the overall efficiency of supplier management. By leveraging technology, organizations can gain greater visibility into their supply chain, enabling them to make more informed decisions and better manage their suppliers.

Technology can be used to automate the process of supplier selection and evaluation. Automation can help organizations quickly identify the best suppliers for their needs, reducing the time and effort required to evaluate potential suppliers. Automation can also help organizations track supplier performance over time, allowing them to identify areas of improvement and take corrective action when necessary.

Technology can also be used to facilitate communication between organizations and their suppliers. By leveraging technology, organizations can quickly and easily share information with their suppliers, enabling them to collaborate more effectively. This can help organizations reduce costs associated with supplier management, as well as improve the quality of the products and services they receive.

Technology can also be used to improve the accuracy of supplier data. By leveraging technology, organizations can ensure that their supplier data is up-to-date and accurate, reducing the risk of errors and ensuring that they are making informed decisions. This can help organizations reduce costs associated with supplier management, as well as improve the quality of the products and services they receive.

Finally, technology can be used to improve the security of supplier data. By leveraging technology, organizations can ensure that their supplier data is secure and protected from unauthorized access. This can help organizations reduce the risk of data breaches and protect their suppliers from malicious actors.

In conclusion, technology can be used to optimize supplier management for lower total cost of ownership. By leveraging technology, organizations can gain greater visibility into their supply chain, automate the process of supplier selection and evaluation, facilitate communication between organizations and their suppliers, improve the accuracy of supplier data, and improve the security of supplier data. By leveraging technology, organizations can reduce costs associated with supplier management, as well as improve the quality of the products and services they receive.

Conclusion

In conclusion, Supplier Management Strategies for the Lowest Total Cost of Ownership (TCO) are essential for any business looking to maximize their profits and minimize their costs. By carefully selecting and managing suppliers, businesses can ensure that they are getting the best value for their money and that their suppliers are providing quality products and services. Additionally, businesses should strive to develop long-term relationships with their suppliers to ensure that they are getting the best possible deals and that their suppliers are meeting their expectations. By following these strategies, businesses can ensure that they are getting the lowest total cost of ownership and that their suppliers are providing the best value for their money.

Supplier Management Resources

- End To End SCM Process

- Emerging Technologies Improve Supply Chain: AI, AR, Blockchain, IoT, RPA, Robots…

- Guide to Negotiations.

- Guide to Strategic Sourcing.

- How to Eliminate Cost in the Supply Chain.

- How To Get What You Want Every Time: ex FBI agent Chris Voss.

- Procurement Quotes by Top Minds.

- Strategies to Reduce Procurement Costs with Suppliers.

- SCM Collaboration on Social Media.

- Supply Chain Resources by Topic & Supplier

- Supply Chain Today: Supply Chain Research, News, and Training.

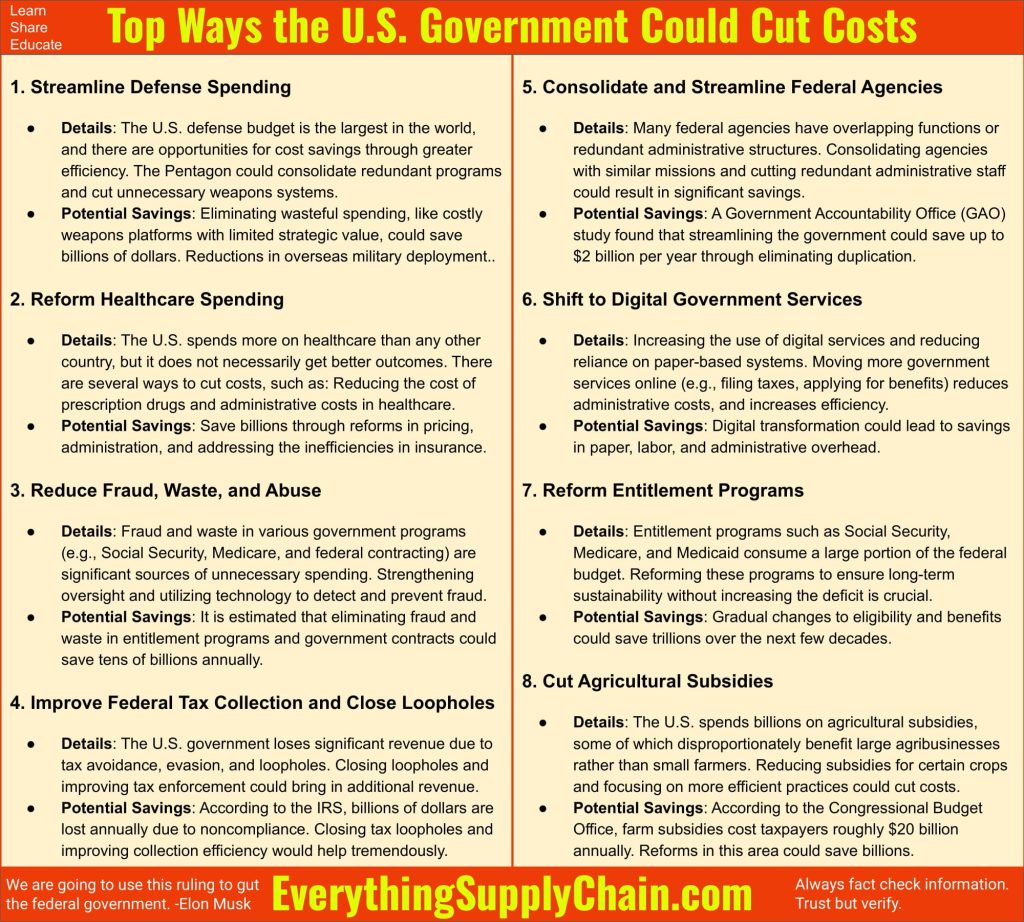

Ways Elon Musk Might Gut the Federal Government.

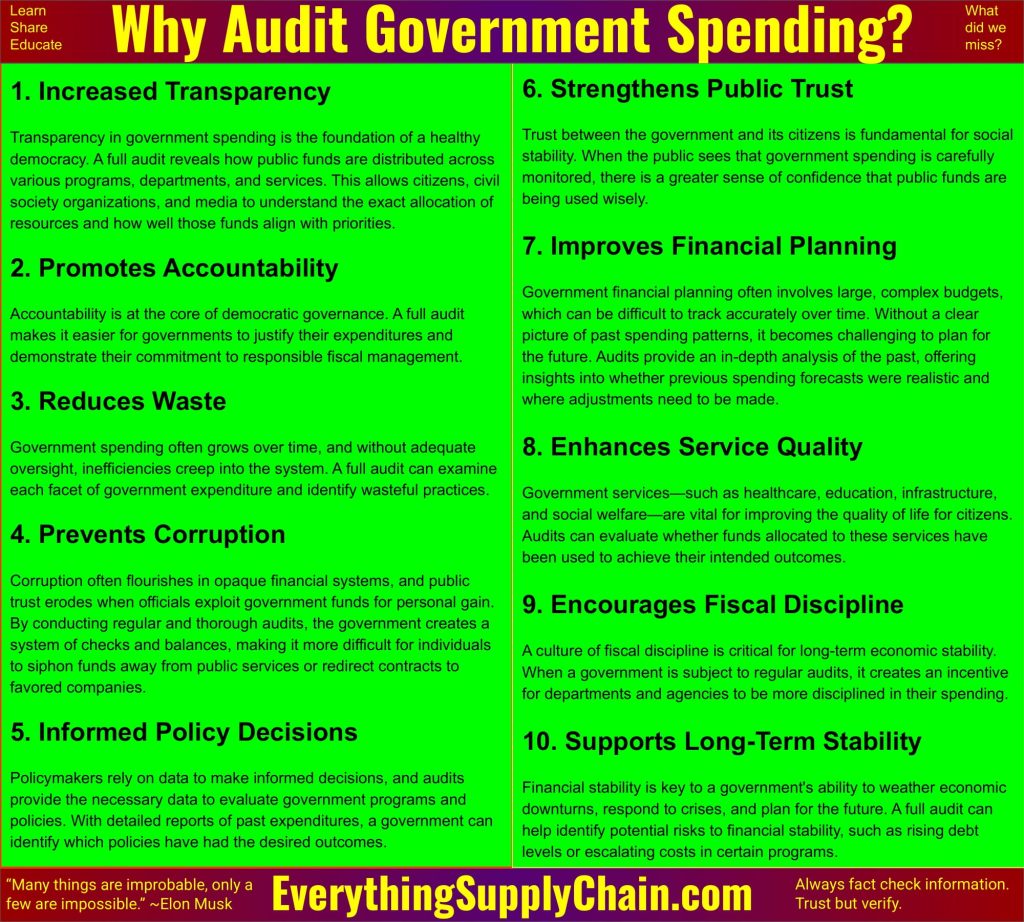

Why Audit Government Spending?

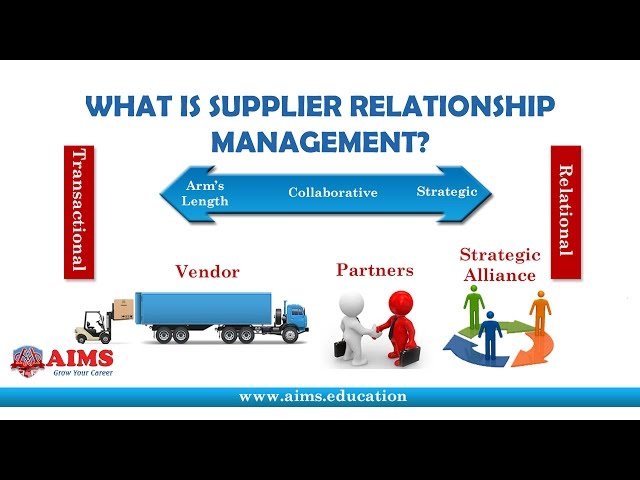

What is Supplier Relationship Management?

Strategic Sourcing – Supply Chain Today

Are Trump’s Tariffs a Negotiation Strategy?

Guide to Supplier Management.