The Beer Game – Supply Chain Management

The Beer Game – Inventory Management

Professors Brad Morrison, Jim Hines, and Paulo Gonçalves teach their organizational behavior and supply chain management classes how to play the beer game.

The Supply Chain Beer Game is a popular educational simulation game designed to illustrate key concepts in supply chain management, such as demand fluctuation, the bullwhip effect, and coordination challenges across a supply chain network. It was originally developed in the early 1960s by professors at the MIT Sloan School of Management, particularly as part of the system dynamics work pioneered by Jay Forrester.

Objective of the Game

The game’s objective is to simulate the dynamics of a typical supply chain in the beer industry, where multiple parties (retailer, wholesaler, distributor, and factory) work together to meet customer demand. The challenge is to manage inventory while minimizing costs related to stockouts (when customer demand exceeds supply) and overstock (when supply exceeds demand).

How the Beer Game Works

- Supply Chain Roles: The beer game involves four roles in the supply chain:

- Retailer: Receives customer orders and sells beer directly to consumers.

- Wholesaler: Supplies beer to the retailer.

- Distributor: Supplies beer to the wholesaler.

- Factory: Produces beer and supplies it to the distributor.

- Flow of Beer and Information:

- The factory produces the beer, which flows downstream through the supply chain (from the distributor to the wholesaler, wholesaler to the retailer, and finally to the customer).

- Orders are placed upstream in the supply chain (from the retailer to the wholesaler, wholesaler to distributor, and distributor to factory).

- Information about customer demand is usually delayed as it travels up the supply chain.

- Gameplay Dynamics:

- Each participant in the supply chain tries to fulfill the demand of the player next in line. For example, the retailer tries to meet consumer demand, the wholesaler tries to meet the retailer’s demand, and so on.

- However, each player can only see the demand from their direct customer, not the overall demand downstream or upstream.

- Players place orders based on demand, but there are delays in receiving the products due to production lead time and shipping.

- Key Constraints:

- Players face limited visibility of the entire supply chain.

- There are time delays between ordering and receiving products.

- Communication is often restricted to the immediate demand from the next link in the chain.

- Bullwhip Effect:

- One of the key outcomes demonstrated by the beer game is the bullwhip effect, where small fluctuations in customer demand can cause much larger fluctuations in demand orders upstream in the supply chain. This happens because each player tends to overcompensate for perceived demand changes, leading to inefficiencies such as overproduction, stockouts, or excessive inventory.

How the Game Unfolds

- Initially, customer demand is stable, but as orders move up the supply chain, delays and miscommunication often cause fluctuations. The lack of coordination leads to larger orders than necessary, causing the inventory to fluctuate wildly.

- For example, if the retailer experiences a small spike in customer demand, they might increase their orders to the wholesaler. In response, the wholesaler increases their order to the distributor even more, causing a ripple effect that amplifies as it moves upstream to the factory.

- Over time, these fluctuations become more pronounced as the supply chain experiences periods of both overstock and shortages.

Learning Objectives

The beer game helps participants understand several key concepts in supply chain management:

- Bullwhip Effect: Demonstrates how small variations in demand can be amplified in the supply chain due to delays, lack of visibility, and overreaction to demand changes.

- Importance of Communication: Highlights the need for better communication and information sharing across the supply chain to reduce uncertainty and inefficiencies.

- Inventory Management: Shows how inventory management strategies need to balance between avoiding stockouts and minimizing excess inventory.

- System Dynamics: Illustrates the impact of feedback loops and delays on system behavior, which is central to system dynamics and supply chain management.

Origins of the Beer Game

The beer game was developed as part of a larger effort at MIT to explore system dynamics, a field pioneered by Jay Forrester. System dynamics focuses on understanding the behavior of complex systems over time, including feedback loops and time delays that can lead to unpredictable behavior. The beer game was originally designed to demonstrate the dynamics of a multi-stage supply chain, but it has since become a widely used tool in business schools and corporate training programs around the world to teach supply chain management principles.

The simplicity of the beer game makes it accessible, while the complexity of the underlying dynamics provides valuable insights into real-world supply chain challenges.

Quotes on Supply Chain

- “Eighty-five percent of the reasons for failure are deficiencies in the systems and process rather than the employee. The role of management is to change the process rather than badgering individuals to do better.” ~W. Edwards Deming

- “If supply chain had an arch enemy it would be called ‘Bad Communication’.” ~Dave Waters

- “One of the only ways to get out of a tight box is to invent your way out.” ~Jeff Bezos

- “Almost all quality improvement comes via simplification of design, manufacturing, layout, processes, and procedures.” ~Tom Peters

- “Bullwhip Effect: Shifts in customer demand are magnified the farther you move up the supply chain. This leads to large fluctuations in inventory.” ~EverythingSupplyChain.com.

- “The future of collaboration is the metaverse.” ~Dave Waters

- “Today’s leading real-world retailer, Wal-Mart, uses software to power its logistics and distribution capabilities, which it has used to crush its competition.” ~Mark Andreesen

- “Supply Chain is like nature, it is all around us.” ~Dave Waters

- “Everyone should know how to negotiate. If you buy a house, a car, or something off Craigslist, negotiation is important.” ~EverythingSupplyChain.com.

- “Make inventory a common enemy for your company.” ~Dave Waters

Supply Chain Training and Videos

- ABC Analysis in Inventory Management.

- Bullwhip Effect: How Sudden Demand Increases Affect Supply Chains.

- Buy it: Managing Supply.

- How Toxic Employees Get Promoted – Don’t Let It Happen.

- Inventory Management Cheat Sheet.

- Inventory Management Training in 3 minutes – ABC Classification

- Kanban explained in 60 seconds. 11k views.

- Min-Max Inventory Supply Chain Strategies.

- SCM Master: Professor Hau Lee on the bullwhip effect.

- Supply Chain Resources by Topic & Supplier.

- The Bullwhip Effect 101.

- What is Supply Chain Management?

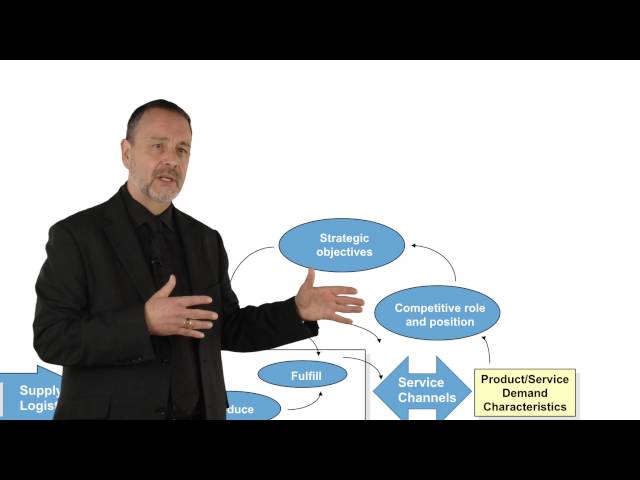

Developing Supply Chain Strategy

Guide to Strategic Sourcing.

PROCUREMENT MANAGER Interview Questions And Answers

How Overnight Shipping Works – such as UPS, FedEx, DHL.

Your Guide to the Amazon Supply Chain.

Guide to the Apple Supply Chain.